Multiple Injection Strategy for High-Pressure Combustion

In a related engine research project, isobaric combustion has been achieved at pressures up to 150 bar. This operation has demonstrated a significant efficiency improvement, particularly with gasoline-like fuels. This was achieved with multiple repetitive short injections. The same thermodynamic conditions have been reproduced in a CVCC to study the fundamentals of spray to spray interaction at extremely high densities.

Characterization of H2 spray at low density

In this project, we are using a constant pressure flow vessel to study the mixing of H2 with air at pressure and temperature conditions that are relevant to engines operated with direct injection of hydrogen.

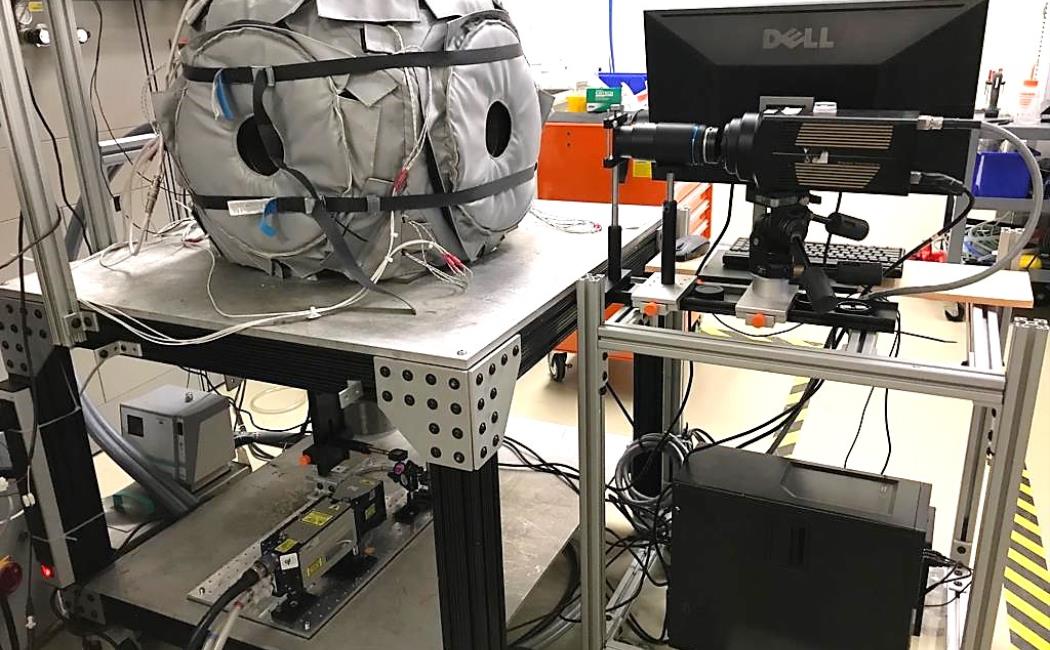

Characterization of Diesel sprays at high density in a CVCC

The characterization of liquid fuel injection at high pressures (up to 1500 bar) into a high-density ambient air allows the fundamental study of atomization and combustion at conditions relevant to many applications in the transport sector. The injection process involves physical and chemical phenomena that are not fully understood, such as the interaction between the trans-critical spray and the combustion. In this project, we have studied the injection and combustion of Diesel, gasoline, and Primary Reference Fuels (PRF0, PRF50, and PRF100) in the CVCC while operating at 150 bar and 1000 K.