Details

Motivation

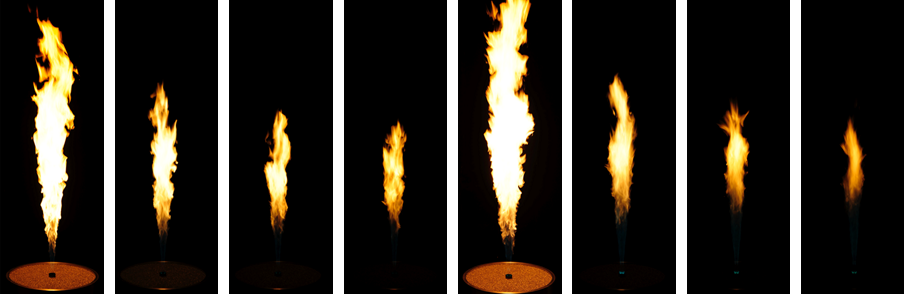

- Develop a complete library of Turbulent Non-Premixed Piloted Flames

- Based on the ethylene flame developed by Zhang, Shaddix & Schaefer at Sandia Laboratories

- Provide experimental validation for turbulent flame modelers

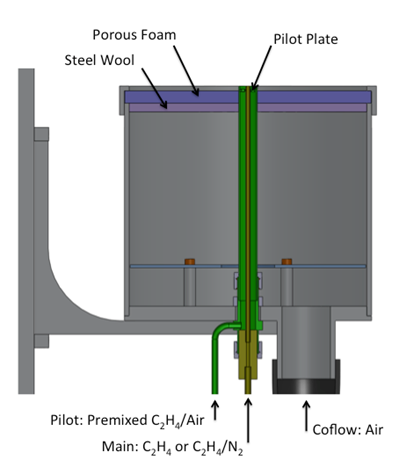

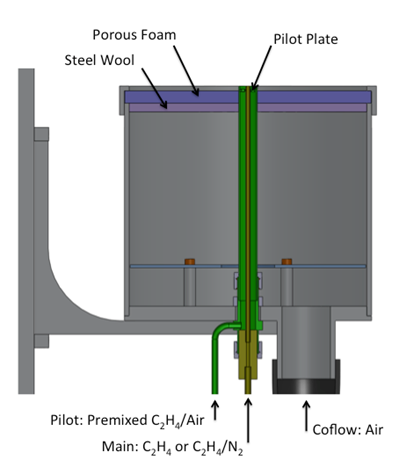

Burner Design

- Central fuel tube

- Delivers ethylene with nitrogen as diluent

- Annular fuel tube

- Delivers premixed ethylene and air for pilot flame (6 % of total heat release)

- Co-flow Air jet

- Concentric tube with an outer diameter of 245 mm including an aluminum foam flow-straightener at its exit section. Co-flow velocity is maintained at 0.6 m/s.

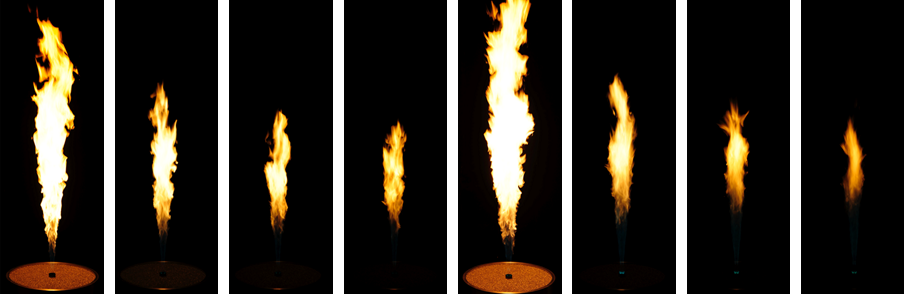

C2H4 Turbulent Non Premixed Flames

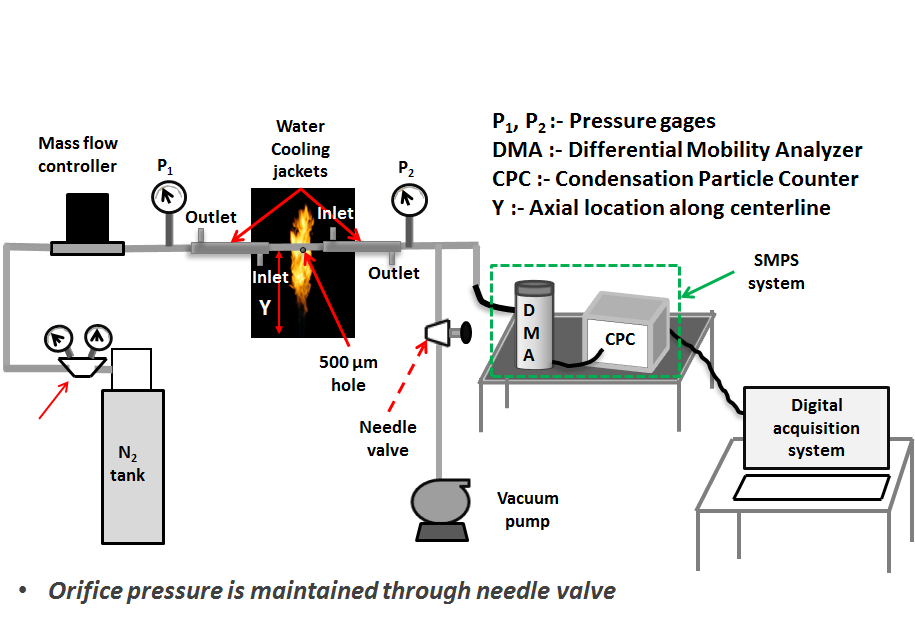

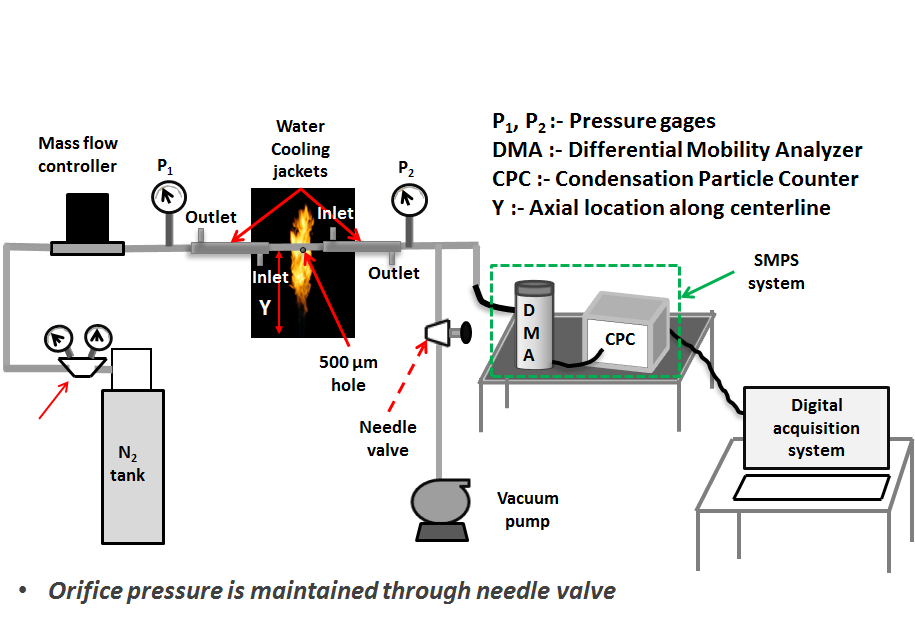

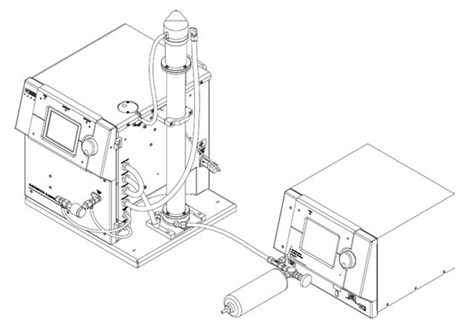

SMPS Setup Schematic

SMPS Constituents - Functions

- Soot measurement is carried out using Scanning Mobility Particle Sizer (SMPS)

- SMPS system consists of

- Electrostatic Classifier

- Impactor: Removes large particles

- Neutralizer: Imparts a known charge distribution

- Differential Mobility Analyzer(DMA):

on aerodynamic drag

- Particle Counter: Counts the number of size selected particles coming out of DMA

Procedure

The sampling of the soot is done through a sampling probe consisting of a 3/8 inch stainless steel tube with a 500 µm orifice. The hole is positioned at various axial distances along the centerline by means of a translation stage. The

amount of sample drawn in through the orifice is dependent on orifice pressure. This is controlled by operating the needle valve shown in the setup. The incoming sample is diluted by nitrogen flown through the tube.

The ends of the sampling tube are cooled by water maintained at 6.5 C to freeze the soot chemistry. A small fraction (1.5 lpm) of the sample is then pulled in by the SMPS and is analyzed to get the soot particle size distribution. The actual

dilution factor is obtained either by gas chromatography or by comparing with laser induced incandescence (LII) measurements to calculate the soot volume fractions in the flame.