30 April, 2015

The rising costs of natural gases continue to prompt governments and industry to seek lower cost fuel alternatives. The Kingdom of Saudi Arabia, for instance, is consuming an increasingly large portion of its own fossil fuels on energy requirements such as air conditioning and water. In the search for a solution, crude oils such as Arabian Super Light (ASL) are being considered as primary or backup fuels for heavy-duty gas turbines. General Electric (GE) and KAUST have recently joined forces to explore the feasibility of using crude oil, straight from the ground, to produce energy.

"GE has about five hundred gas turbines in the Kingdom; and they are the largest provider of gas turbines for power generation by far," said KAUST Professor and Director of the Clean Combustion Research Center (CCRC), William Roberts.

"Saudi Arabia doesn't require all its turbines to be optimally designed to burn any fuel, anytime and anywhere. But, for energy security reasons, having the option to rely on unrefined crude in case of emergency is important," said CCRC Laboratory Manager John McIntosh. "Moreover, distilling fuels is very expensive, so there's an economic incentive for further testing."

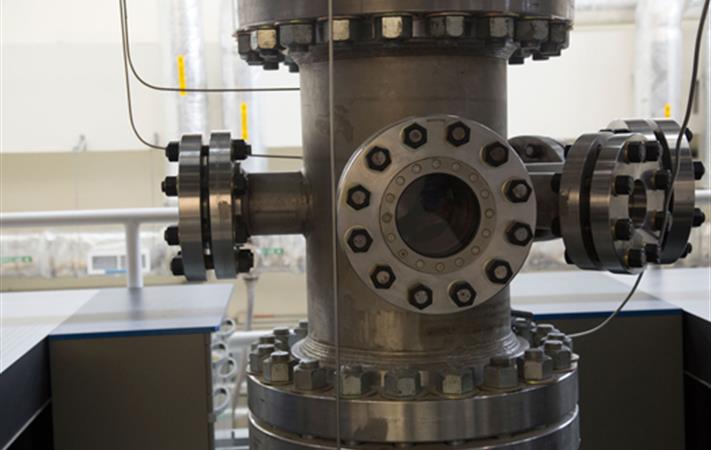

The experiment consists of building a rig at KAUST, through the High Pressure Combustion Laboratory (HPCL), to perform corrosion tests on turbine materials. The rig will burn ASL/AXL crude continuously for 2,000 hours.

A major consideration is how to insulate the test rig to ensure it can withstand extreme pressure and operating temperatures of 900 degrees Celsius or more. As the oil burns, the gases containing the vanadium salts coat the inner walls of the rig. GE carefully selected the HPCL at KAUST as a partner because there are very few laboratories with the capacity to burn crude at such high temperatures and pressures.

As CCRC research technician Jose Maria Silva Corrugedo explained: "We're going to expose different samples during the experiment, to help determine which material is best suited to build the turbines."

Roberts shared: "There are three main issues: efficiency, corrosion and emission for the various fuels that are available not just in the Kingdom but worldwide." The ultimate goal is to understand why vanadium causes corrosion and how that can be prevented.

From the engineering side, the CCRC team wants to look into how to keep the rig operating at high pressure and high temperature without causing the pipes to weaken, leak or blow up. If they get their way, the project will expand to a ten year program, allowing for a greater understanding of corrosion and ultimately leading to significant discoveries to better inform both government and corporate entities.

- by Meres J. Weche, KAUST News