Carbon Capture

Invented for a Changing World

A collaboration between KAUST's Clean Combustion Research Center and Sustainable Energy Solutions LLC (USA).

Our

Technology

KAUST is developing Cryogenic Carbon Capture technology in collaboration with Sustainable Energy Solutions LLC (USA) as a part of the Near Term Grand Challenge. Our technology can capture (remove) CO2 from the exhaust gases of a fossil power plant or an industrial plant (e.g., cement) or any process that releases CO2 in the exhaust. The captured CO2 has >99.99% purity and can be used in most industrial applications.

The

Process

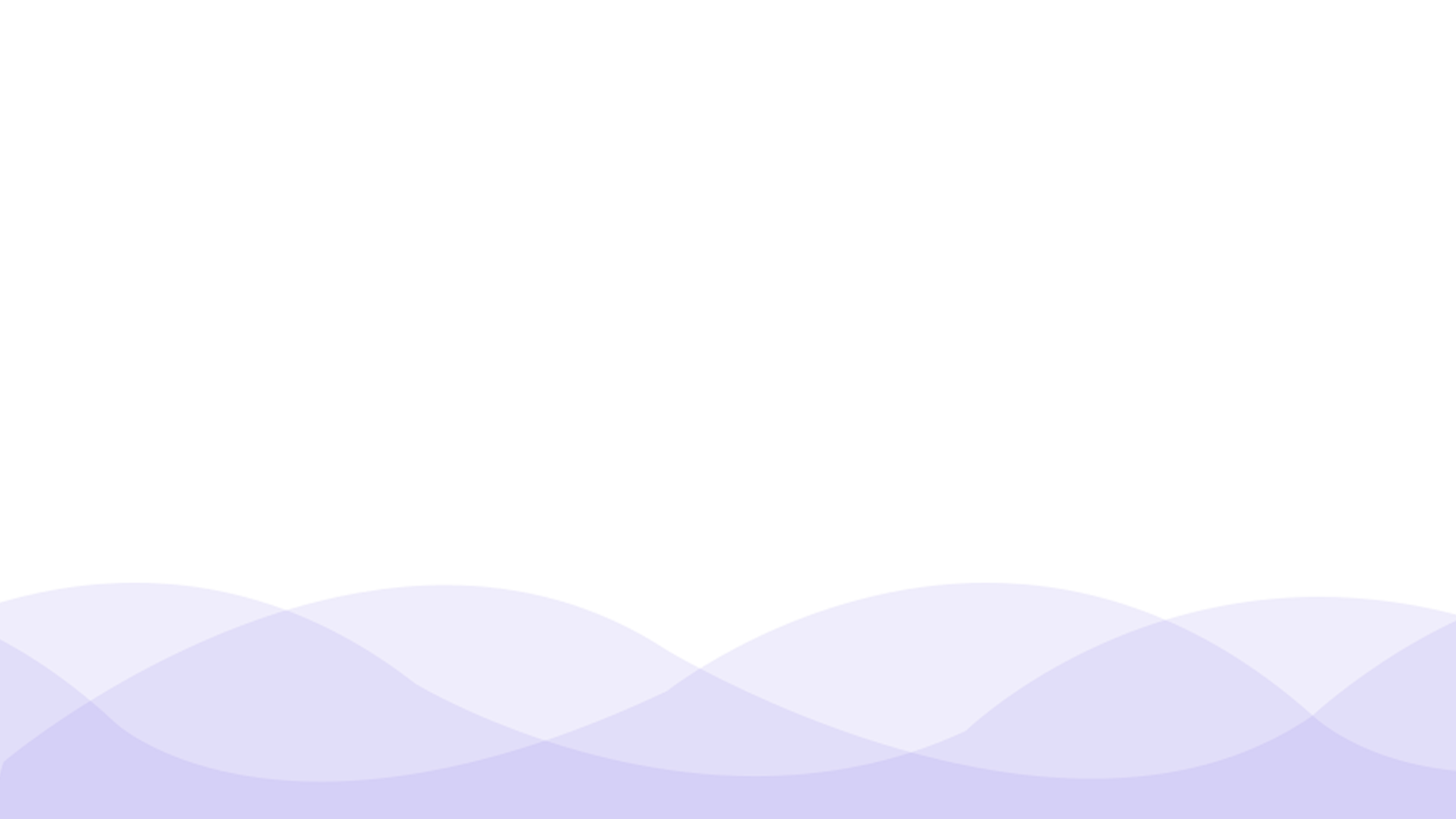

Light gases are reheated and released into the atmosphere

CO2 is captured by cooling the exhaust gases below -130 C using a highly efficient heat transfer system that involves a dryer, a recuperator, and a desublimating heat exchanger, where the CO2 is frozen (solidified) and separated from the rest of the gas (that is now clean). An integrated refrigeration system provides the cooling required for desublimation.

The technology has been demonstrated extensively at a 1 tonne per day CO2 capture rate by SES in the US and it was validated independently at KAUST in Q4-2020 & Q1-2021.

The technology was showcased at the CCI (Circular Carbon Initiative) event hosted by KAUST in December 2020.

In March 2021, a team of technologists from Saudi Aramco, led by their CTO, Ahmed Al-Khowaiter witnessed the demonstration of carbon capture at KAUST. The technology was also showcased to delegates from NEOM. Both these organizations have shown interest in the technology and willingness to actively engage in the technology adoption journey in the Kingdom.

In June 2021, we completed a Pre-FEED (Pre-Front End Engineering Design) study of a 30 tonne/day CO2 capture commercial-scale system for deployment at the Integrated Solar Combined Cycle plant at Duba. The Circular Carbon Economy-National Program, an initiative from the Ministry of Energy, is actively looking at the commercialization of the CCC technology in the Kingdom.

Unmatched

Benefits

Latest Development

Update

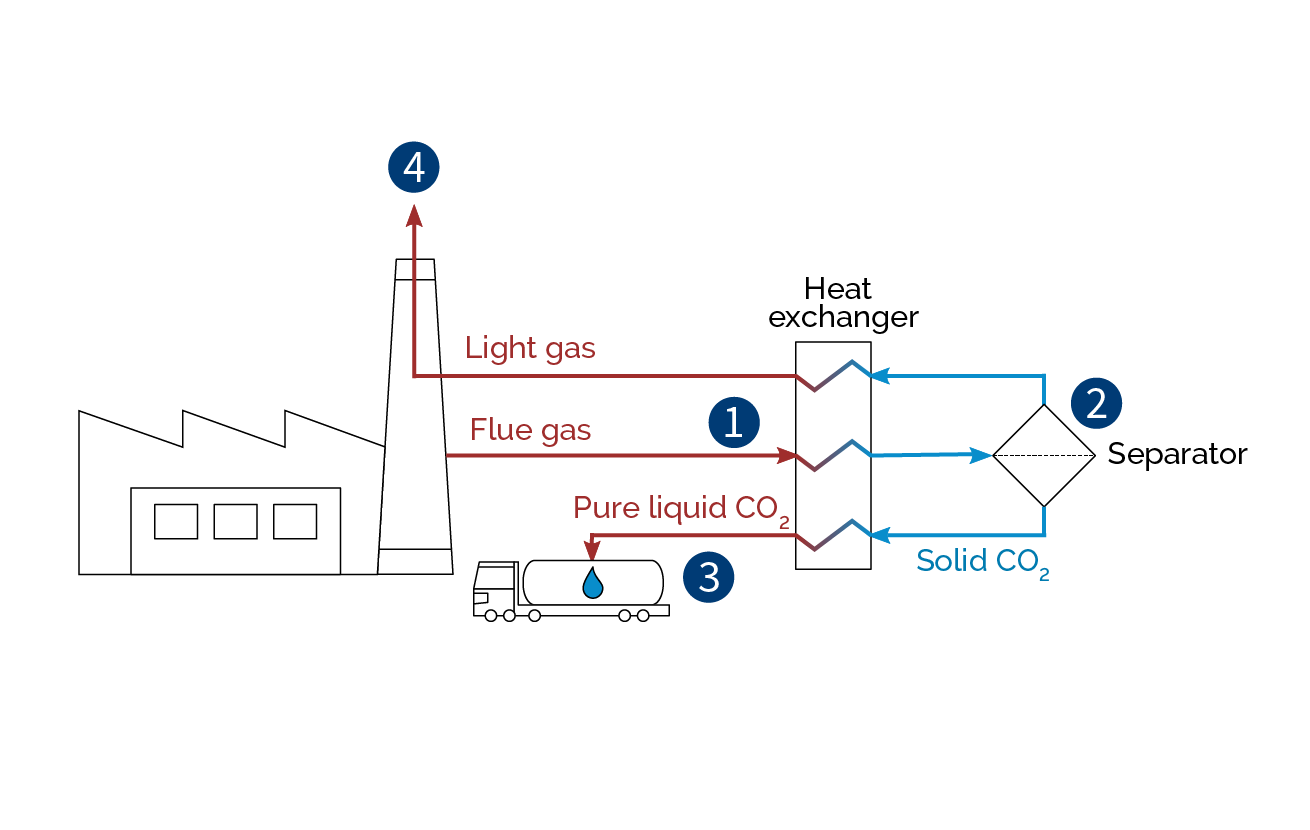

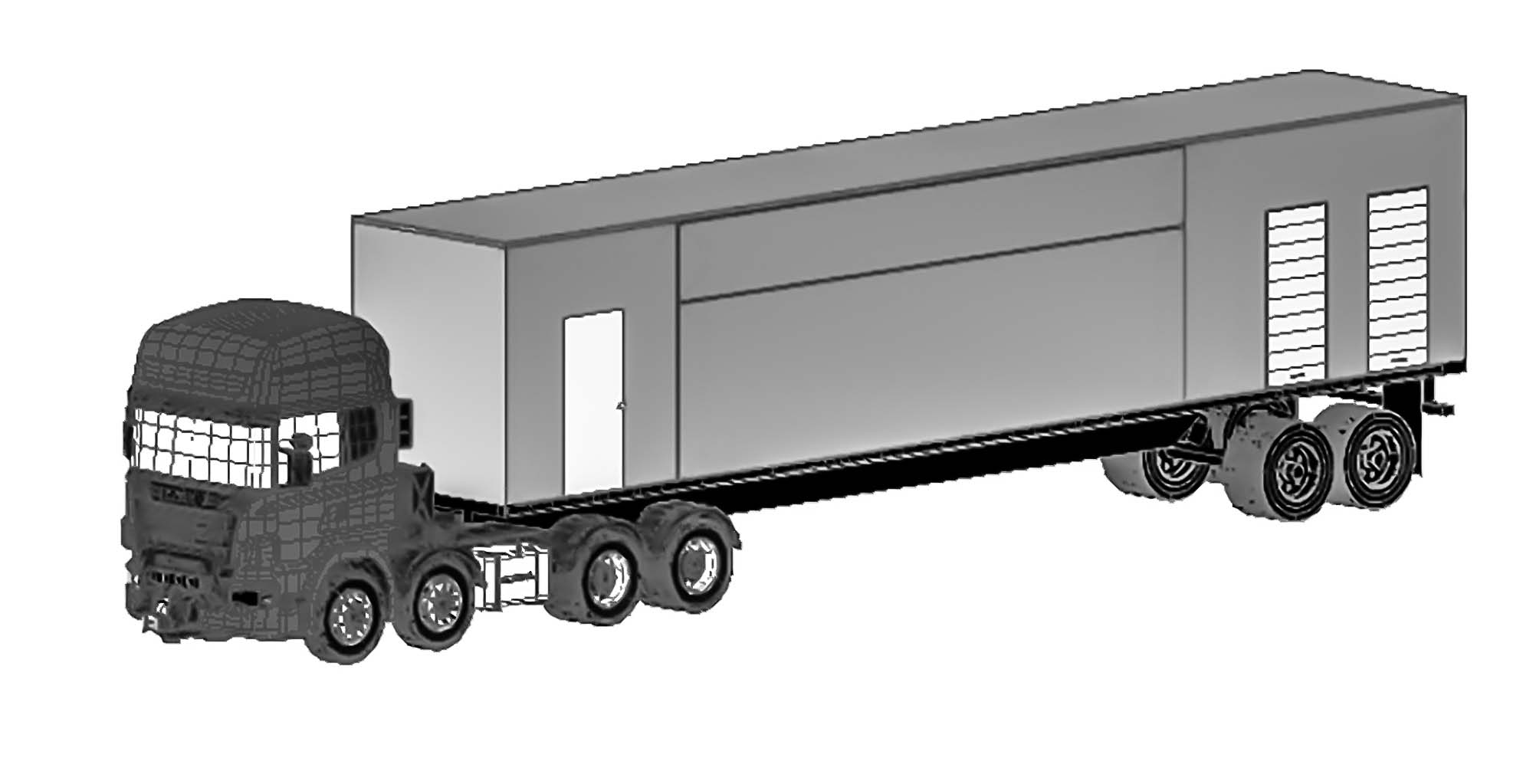

KAUST is currently developing a trailer-mounted CCC skid that can be easily transported to different test sites in the Kingdom. This skid will also have the capability onboard to handle other pollutants such as SOx and NOx and will be optimized for operation in the Kingdom. The pilot testing of this skid will be carried out in 2022 at the Rabigh HFO power plant (owned by Saudi Electric Company). This skid will serve as an active bench to develop and test KAUST IP. KAUST researchers are currently working on a novel direct contact heat exchanger design.

Contact us

for more information